FAQs

A word from K&P Engineering, manufacturer of the world’s finest oil filters:

“Thank you for your interest in our filters. We think it’s great that people are calling attention to the importance of oil and it’s filtration. The more information we can get to people like you the more our product will stand above the competition. Remember, oil is the lifeblood of your machine….. keep it clean!”

Frequently Asked Questions

1) Where is the K&P Engineering filter made?

Proudly designed, engineered, sourced and manufactured in the USA. Make sure you receive a genuine K&P Engineering product.Back to Top

2) Has this type of filtration technology been proven?

This type of filtration has been in use for many many years and has proven itself in NASCAR, Formula One, the Military and in the Aerospace industry. We have been inventing, designing engineering and manufacturing oil filters using this proven technology since 1995. K&P Engineering also manufactures oil filters that are FAA approved for certified aircraft.

3) What kind of materials are used in the K&P Engineering oil filters?

The filter housing and filter element end caps are carved out of a solid chunk of 6061T6 billet aluminum, which not only looks great but aids in dissipating heat and reducing weight. The filter element is made from medical grade, type 304 stainless steel micronic filter cloth to provide unmatched protection against oil contamination and resultant engine damage. A super strength neodymium rare earth magnet is installed in the top of the filter element used in the spin on models, which provides magnetic pre-filtering of the oil. The adhesive used in the filter assembly process is good to 600 degrees Fahrenheit, far above normal operating temperature of 180 to 300 degrees. The hydraulic quad-ring gasket doubles the seal between the filter housing and the engine and helps provide burst pressures exceeding 1000 psi.Back to Top

4) How does this type of filtration compare to paper oil filters?

We use ASTMF316 testing procedures which eliminate many of the user variables found in the SAE procedures. Basically, the filter media is pressurized from one side, and when the media starts passing particles, that is the micron rating. We sent filter media from several common brands of paper filters to the lab to be run through the ASTM test. We sent the media to the lab with no names, just numbers for identification so they wouldn’t have any idea what brand filter they were testing. The results for the paper filters ranged from 48 microns for the best filter to over 300 microns for the worst filter. Our tests were right in line with other testing results we have researched that have paper media filters passing particles anywhere between 50 and 90 microns. What does this mean? Paper filters are rated on averages, percentages of efficiency (also known as beta ratios) and multiple passes, so a 10 micron rated paper filter (as advertised on the packaging) may be letting particles 50 microns and larger through. The medical grade stainless steel cloth that we use is consistent across the entire media surface and is rated at 35 microns, meaning nothing larger than 35 microns should pass through the material. The bottom line is we meet or exceed the filtration performance of OEM filters, eliminating any warranty issues.Back to Top

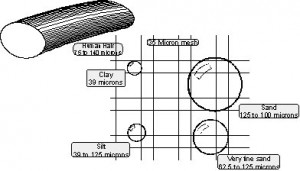

5) What Are Microns?

A micron is one thousandth of a millimeter. That’s approx. .00003937 inches.

35 microns is about .00138″, (just over one-thousandth of an inch).

The lower limit of visibility to the human eye is about 40 microns.

Pollens range from about 30 to 50 microns

A white blood cell is about 25 microns

Cigarette smoke is about 10 microns

6) What about flow rate and why is it so important?

A very important dimension of oil filters is the flow rate. It doesn’t matter how good the filter media is if the oil is going through the bypass due to a low flow rate. We believe many people mistakenly chase smaller and smaller micron ratings to try to get cleaner oil. Flow rate is decreased exponentially as the micron rating is decreased. Again, once the flow is restricted to the point the bypass opens, the filter media rating becomes a moot point. This is why we meet or exceed the filtration of the factory filters to meet warranty requirements, while concentrating on providing maximum flow. This combination delivers the maximum combined benefit from the oil filter. A one-inch square of our filter material can flow 1.9 gallons of oil per minute at only 1-PSI pump pressure (70 degrees F). This means the stainless steel filter cloth we use in our small spin on filter element can flow 57 gals/minute.

We have run static pressure tests between our filters and paper filters for an identical application. For the same sized filters, our stainless steel micronic filter consistently flowed over 7 times more oil for the same time period than did the paper filter (tests were run at 68 degree ambient temperature). How does this affect what is going on inside your engine? We installed pressure gauges on each side of the filter element on a pro stock drag race engine so we could measure differential pressures (the difference in pressure between the input side of the filter element and the output side of the element). During a full pass down the strip the differential pressure of the stock paper filter measured 20psi difference. Our filter measured less than 1psi difference. Less differential pressure means less chance of bypass operation, faster oil pressure at start up, less drag on the oil pump (potential horsepower gains) and higher flow through the engine, often helping to cool the oil and keep the crankcase cleaner.

Another thing that can affect the paper filter flow is moisture. Not everyone is aware that engines get condensation in them. When paper gets wet it swells and may pass even less oil.

Now, think about all the particulates that have had a chance to settle to the bottom of the oil pan right where the oil pickup is… just waiting to go through the bypass valve directly to the engine components…Back to Top

7) Will this filter affect the performance of my engine?

The reduction of back pressure against the oil pump will result in varying amounts of horsepower gain. It depends on your specific engine combination and application. We have seen as much as 5 hp gain, to very little or no gain depending on the drag the oil pump is producing in a specific circumstance. It is definitely not going to reduce performance. There are a couple of sample dyno charts in the “technical” tab of this web site. The higher oil flow through the engine along with the heat dissipation provided by the finned aluminum housing usually results in cooler oil temperatures which can help with performance as well and engine life.Back to Top

8) Why do you promote inspecting the filter contents?

Mechanics have been cutting oil filters apart for ages. It’s one more way to “read” what is happening in the engine. Our filter makes it much easier than cutting apart messy paper filters. By checking the particles that get caught in the filter you can identify abnormal wear and prevent catastrophic engine failure. It’s a lot less aggravating to replace a rod bearing that’s starting to go, than to be standing next to your machine staring at that same rod sticking out the side of the engine!Back to Top

9) What is K&P Engineering doing to help protect the environment?

With the cleanable, reusable design you no longer will be sending oily paper filters to the landfills (some states don’t even allow oil filters to go to the landfills…they must go to through special, expensive disposal processes). What does come out of the reusable filter during cleaning can be sent to the recycling center with the rest of your old oil. All of this helps prevent water and soil contamination. In addition, the environmental impacts of creating new paper filters is reduced, from steel production, media production, glue and painting. This oil filter truly is a renewable resource.Back to Top

10) I have a high oil pressure application and need a high burst pressure similar to specialized paper racing filters. How much pressure will the K&P Engineering filter take?

Our spin on filters have been pressure tested to over 1000 psi. Let us know if you need more than that.Back to Top

11) Why don’t you have an Anti Drain back Valve?

Many filters have a rubber flap over the intake holes that is an attempt to keep oil in the filter and minimize the time it takes to fill the filter when you start the engine (they call it an anti-drain back valve). A test you can perform to see how well this “valve” works is to fill a filter with oil, plug the large center spin on hole with a bolt, lay it on it’s side and then see how long it takes for the oil to drain past the rubber flap. We have found (and have read other published tests) that the filter eventually ends up with the same amount of oil in it as if it didn’t have the flap, it just takes longer to drain out. If the flap worked as planned it would be beneficial to have the extra oil in the filter at start up. On the other hand, that flap covering the intake holes is one more restriction the oil has to get by to get through the filter and back to the motor. All of our testing shows the K&P Engineering filter with it’s ultra low resistance to flow builds oil pressure in the engine components faster than a paper filter that has the anti drain back.Back to Top

12) How much oil does this filter hold?

Slightly more or less than the stock filter depending on the specific application. It doesn’t really make any difference because of our filtration and flow capabilities. Continue to use your manufacturer’s prescribed method of checking to make sure there is the proper amount of oil in the engine (usually via a dipstick).Back to Top

13) How do I install and remove the K&P Engineering filter?

A cup wrench is included with almost all of our spin on filters that mates to the 14 flats machined into the bottom rib of the housing. Please reference the Cleaning and Installation tab on this website for detailed instructions.Back to Top

14) What if I accidentally ruin the filter element (I stepped on mine…)?

Not to worry…individual replacement parts are available through your dealer.Back to Top

15) How do I clean the filter?

Please reference the Cleaning instructions tab on this web site.Back to Top

16) Tell me about the filter sealing gasket (Quad Ring).

Our housings are designed and specially machined to utilize a quad ring as the sealing mechanism between the housing and the mounting surface. Quad rings are commonly found in hydraulic applications and have a high re usability factor. Along with our engineered housings, we have achieved burst pressures that exceed 1000 psi. You normally will be able to use the same quad ring for several oil changes. If needed, you can flip the quad ring over and use the other side for an additional oil change. A single quad ring can last for several years. New filter kits have a spare included in the packaging. Quad rings are more sensitive to dirt than the old square gaskets so make sure the mounting surface and quad ring are both free of debris before installing the filter. If you have had a quad ring tear, make sure you don’t have any burrs on the mounting surface, and be sure to lube the quad ring well with oil before installing the filter onto the engine or remote mount. Replacement quad rings should be available through the majority of our dealers, or can be found at larger o-ring supply shops. The quad rings are non-proprietary industry standard parts.

If you have difficulty locating a replacement, contact us and we’ll get you the industry standard part number as well as help you find a source.Back to Top

17) Will this filter affect my warranty?

No. Under the Magnuson-Moss Warranty Act, 15 U.S.C. SS 2301-2312 (1982), and the general principles of the Federal Trade Commission Act, a manufacturer may not require the use of any brand of filter unless the manufacturer provides that item free of charge under terms of the warranty. So, if you are told by a dealer that anything other than a specific brand of filter will void your warranty, ask for the statement in writing (you won’t get one), and request that filter be supplied free of charge. If you are charged for the filter, the dealer will be violating the Magnuson-Moss Warranty Act and other applicable law. This is a federal law and the Federal Trade Commission has authority to enforce it, including obtaining injunctions and orders containing affirmative relief. For more info do an Internet search on “Magnuson-Moss Warranty Act”, specifically items related to “Tie-In Sales” Provisions.

The links below will take you to some associated documents on the the FTC website, including warnings from the FTC to vehicle manufacturers about making claims aftermarket products will void your warranty.

This is the section in the Magnuson-Moss Warranty Act that specifically addresses the issue: [42 FR 36114, July 13, 1977, as amended at 80 FR 42721, July 20, 2015]

700.10 Prohibited tying.

(a) Section 102(c), 15 U.S.C. 2302(c), prohibits tying arrangements that condition coverage under a written warranty on the consumer’s use of an article or service identified by brand, trade, or corporate name unless that article or service is provided without charge to the consumer.

(b) Under a limited warranty that provides only for replacement of defective parts and no portion of labor charges, section 102(c), 15 U.S.C. 2302(c), prohibits a condition that the consumer use only service (labor) identified by the warrantor to install the replacement parts. A warrantor or his designated representative may not provide parts under the warranty in a manner which impedes or precludes the choice by the consumer of the person or business to perform necessary labor to install such parts.

(c) No warrantor may condition the continued validity of a warranty on the use of only authorized repair service and/or authorized replacement parts for non-warranty service and maintenance (other than an article of service provided without charge under the warranty or unless the warrantor has obtained a waiver pursuant to section 102(c) of the Act, 15 U.S.C. 2302(c)). For example, provisions such as, “This warranty is void if service is performed by anyone other than an authorized `ABC’ dealer and all replacement parts must be genuine `ABC’ parts,” and the like, are prohibited where the service or parts are not covered by the warranty. These provisions violate the Act in two ways. First, they violate the section 102(c), 15 U.S.C. 2302(c), ban against tying arrangements. Second, such provisions are deceptive under section 110 of the Act, 15 U.S.C. 2310, because a warrantor cannot, as a matter of law, avoid liability under a written warranty where a defect is unrelated to the use by a consumer of “unauthorized” articles or service. In addition, warranty language that implies to a consumer acting reasonably in the circumstances that warranty coverage requires the consumer’s purchase of an article or service identified by brand, trade or corporate name is similarly deceptive. For example, a provision in the warranty such as, “use only an authorized `ABC’ dealer” or “use only `ABC’ replacement parts,” is prohibited where the service or parts are not provided free of charge pursuant to the warranty. This does not preclude a warrantor from expressly excluding liability for defects or damage caused by “unauthorized” articles or service; nor does it preclude the warrantor from denying liability where the warrantor can demonstrate that the defect or damage was so caused.

These are the Magnuson-Moss Warranty Act links below:

https://www.consumer.ftc.gov/articles/0138-auto-warranties-routine-maintenance#will

https://www.ftc.gov/tips-advice/business-center/guidance/businesspersons-guide-federal-warranty-law