[vc_row][vc_column]

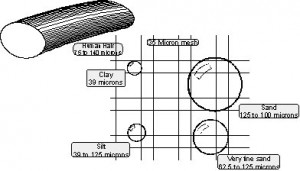

A micron is one thousandth of a millimeter. That’s approx. .00003937 inches.

35 microns is about .00138″, (just over one-thousandth of an inch).

The lower limit of visibility to the human eye is about 40 microns.

Pollens range from about 30 to 50 microns

A white blood cell is about 25 microns

Cigarette smoke is about 10 microns

A very important dimension of oil filters is the flow rate. It doesn’t matter how good the filter media is if the oil is going through the bypass due to a low flow rate. We believe many people mistakenly chase smaller and smaller micron ratings to try to get cleaner oil. Flow rate is decreased exponentially as the micron rating is decreased. Again, once the flow is restricted to the point the bypass opens, the filter media rating becomes a moot point. This combination delivers the maximum combined benefit from the oil filter. A one-inch square of our filter material can flow 1.9 gallons of oil per minute at only 1-PSI pump pressure (70 degrees F). This means the stainless steel filter cloth we use in our small spin on filter element can flow 57 gals/minute.

We have run static pressure tests between our filters and paper filters for an identical application. For the same sized filters, our stainless steel micronic filter consistently flowed over 7 times more oil for the same time period than did the paper filter (tests were run at 68 degree ambient temperature). How does this affect what is going on inside your engine? We installed pressure gauges on each side of the filter element on a pro stock drag race engine so we could measure differential pressures (the difference in pressure between the input side of the filter element and the output side of the element). During a full pass down the strip the differential pressure of the stock paper filter measured 20psi difference. Our filter measured less than 1psi difference. Less differential pressure means less chance of bypass operation, faster oil pressure at start up, less drag on the oil pump (potential horsepower gains) and higher flow through the engine, often helping to cool the oil and keep the crankcase cleaner.

Another thing that can affect the paper filter flow is moisture. Not everyone is aware that engines get condensation in them. When paper gets wet it swells and may pass even less oil.

Many filters have a rubber flap over the intake holes that is an attempt to keep oil in the filter and minimize the time it takes to fill the filter when you start the engine (they call it an anti-drain back valve). A test you can perform to see how well this “valve” works is to fill a filter with oil, plug the large center spin on hole with a bolt, lay it on it’s side and then see how long it takes for the oil to drain past the rubber flap. We have found (and have read other published tests) that the filter eventually ends up with the same amount of oil in it as if it didn’t have the flap, it just takes longer to drain out. If the flap worked as planned it would be beneficial to have the extra oil in the filter at start up. On the other hand, that flap covering the intake holes is one more restriction the oil has to get by to get through the filter and back to the motor. All of our testing shows the K&P Engineering filter with it’s ultra low resistance to flow builds oil pressure in the engine components faster than a paper filter that has the anti drain back.

Slightly more or less than the stock filter depending on the specific application. It doesn’t really make any difference because of our filtration and flow capabilities. Continue to use your manufacturer’s prescribed method of checking to make sure there is the proper amount of oil in the engine (usually via a dipstick).

A cup wrench is included with almost all of our spin on filters that mates to the 14 flats machined into the bottom rib of the housing. Please reference the Cleaning and Installation tab on this website for detailed instructions.

Not to worry…individual replacement parts are available through your dealer.

Please reference the Cleaning instructions tab on this web site.

If you have difficulty locating a replacement, contact us and we’ll get you the industry standard part number as well as help you find a source.

FILTER LOOKUP

Enter current paper filter number and Find Our Replacement!

Enter current paper filter number and Find Our Replacement!

(“As I said before, I was a reluctant convert to the K and P filter, but, now am a die-hard fan. And now I have even more to “crow” about………this customer service ranks among the top 4 or 5 in my lifetime. Congratulations on a great product and thanks for standing behind it so well……….”

J. Webb